Solutions MACHINE VISION SYSTEMS

What is Machine Vision?

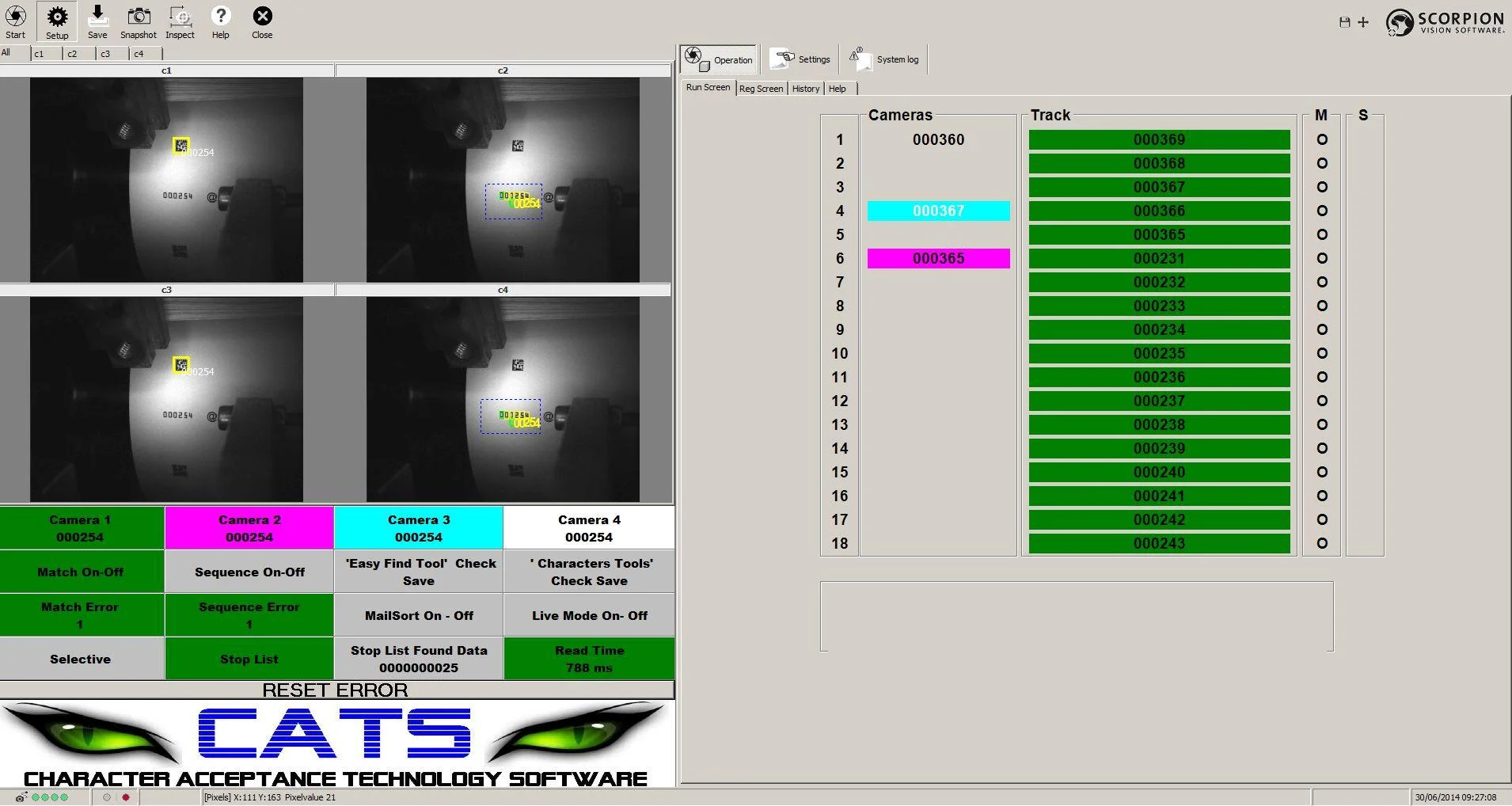

Machine vision is a technology that provides image-based automatic inspection and analysis.

It does this by using machine vision cameras to capture visual information from the surrounding environment and then processing these images with a combination of hardware and software, preparing the information for use in various industrial applications.

Machine vision technology essentially gives industrial equipment the ability to ‘see’. It then makes rapid decisions based on what it sees. This technology is commonly used for visual inspection, defect detection, positioning and measuring parts, identifying, sorting and tracking products, automatic inspection and process control for a wide range of industries.

De-risk Your Project With a Scorpion Vision System

Scorpion Vision automation and robot vision systems are based on our own hardware and software products. Scorpion Vision Software™ is the core technology behind everything we do. We use the Scorpion Vision Stinger™ portfolio of camera products to take control of the unknowns commonly seen in complex system builds.

We have a vast toolbox of techniques and technologies to solve just about any issue. Our collaborative team of machine vision experts deliver solutions using approved project management protocols for task tracking and reporting. And with a designated team leader responsible for successful project completion, you’re looked after from start to finish.

Machine Vision Applications

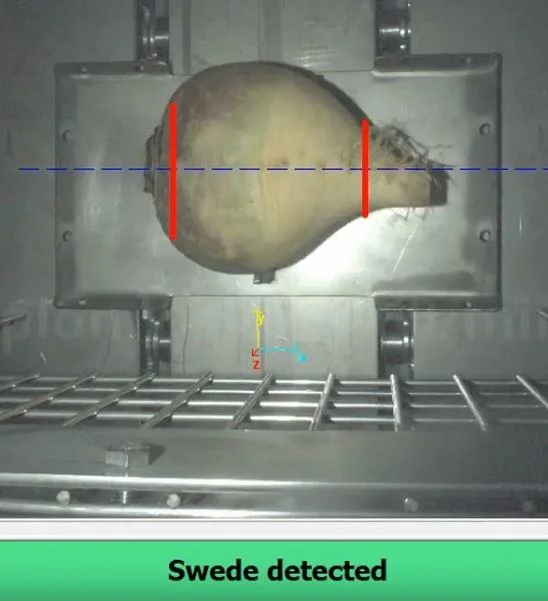

Our machine vision systems are used across many applications and we focus on four main industries: Logistics, for pallet inspection and sorting. Manufacturing, for problem-solving on production lines. Horticulture, for replacing difficult-to-source workforce for fresh product processing. And food, for systems that ensure safe and hygienic food inspection.

Components of Machine Vision

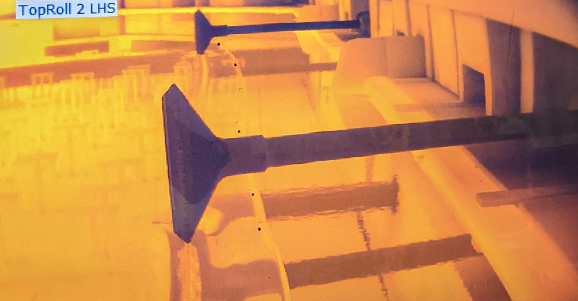

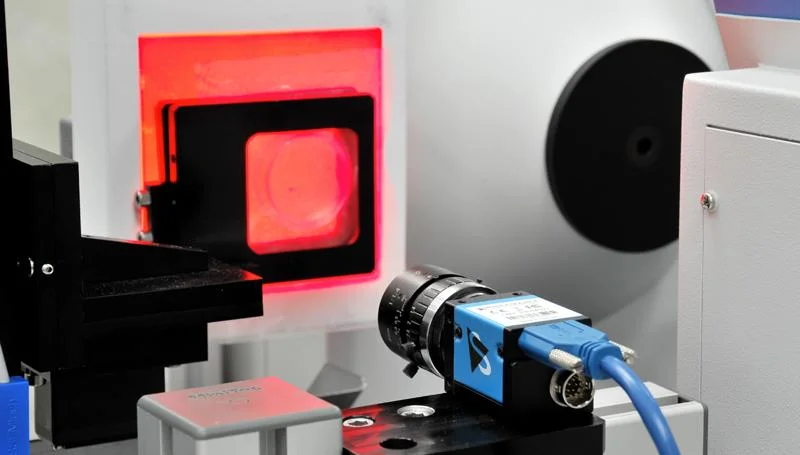

Lighting

Properly illuminating a target ensures correct information and high productivity, making lighting one of the most important components of machine vision.

Staging

Staging ensures the target is correctly placed at centre stage, facing the camera, and rotated if necessary. The target must also be held in place for accurate processing of information.

Lenses

The lens captures the image and delivers it to the image sensor in the camera. Machine vision lenses are robust and designed for frequent use within industrial applications.

Cameras

Machine vision cameras include advanced features required for optimal performance and accuracy in visual inspection and analysis and are designed to withstand harsh operating conditions.

Types of Machine Vision Systems

1D Vision Systems

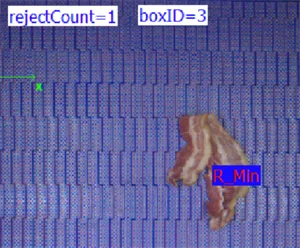

1D machine vision systems analyse the digital signal one line at a time. They are commonly used to detect and identify defects in fast moving inspection applications.

2D Vision Systems

2D machine vision systems provide area scans. They are compatible with most software packages and are the default technology used for most industrial vision systems.

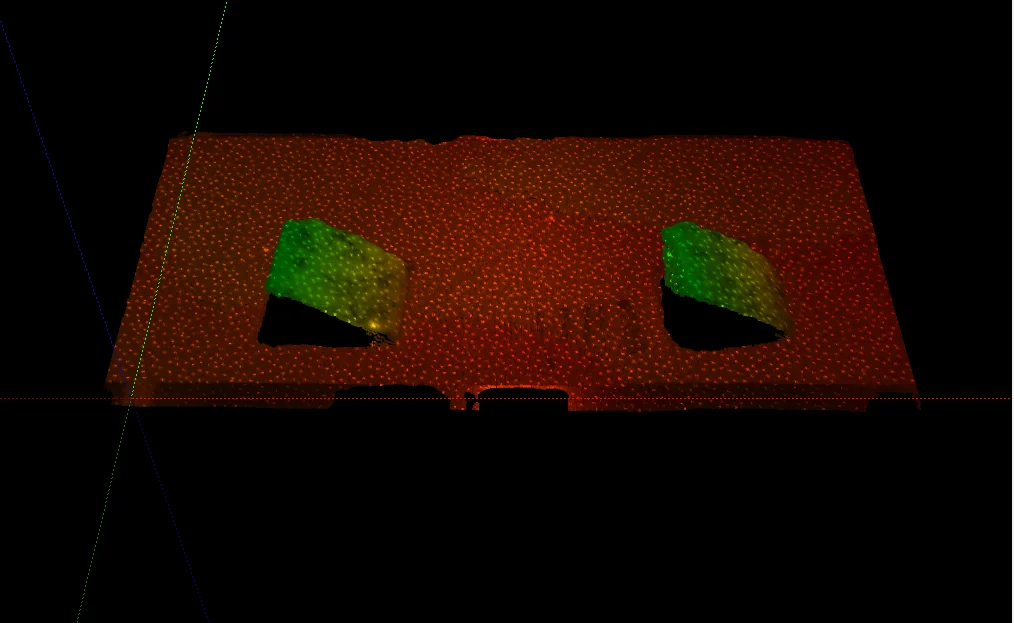

3D Vision Systems

3D machine vision systems add an extra dimension to image analysis. They can see their environment and calculate the location of an object by using multiple cameras.

Area Scan and Line Scan

Area scan cameras are commonly used in applications where a 2D image can display all the elements for inspection. Line scan cameras are used in high-speed processing or fast-moving conveyor line applications in both 2D and 3D profiling.

Machine Vision Projects

- All Industries

- Food

- Horticulture

- Logistics

- Manufacturing

Frequently Asked Questions

Is Machine Vision an AI?

Machine vision uses AI technology to give industrial equipment to see, analyse, make decisions and perform tasks the way a human would.

How do I choose a vision system?

There are many elements to consider when choosing an industrial vision system, such as the application type, whether it’ll require depth perception, the nature of inspection, the speed required, and the accuracy required. If you’re not sure which vision system is right for your project, a member of our team can advise you.

What's the difference between machine vision and computer vision?

Machine vision is the use of computer vision in industrial environments, and computer vision refers to the automation of the capturing and processing of images.

What industries use machine vision?

Any industry with volume production will require a vision system for quality control or optical sorting. Scorpion Vision machine vision systems are often used in food production and processing, manufacturing, textile production, the automotive industry, the healthcare industry, and the transport industry. Get in touch with us to find out how machine vision can solve problems in your industry.

GET IN TOUCH

We are always delighted to hear from our customers. If you’d like to ask a question, make an enquiry or request support, please contact us through one of the methods below or by using the enquiry form.

Telephone: +44 (0) 1590 679333

Sales: [email protected]

Technical: [email protected]