Projects High Speed Carbon Fibre Measurement and Inspection

Background

Red Composites is one of Europe’s leading suppliers of towpregs, which are ribbons of carbon fibre or glass fibre pre-impregnated with an epoxy resin and wound onto a spool.

Red Composite’s towpregs are generally used in the winding of tubular components in a diverse range of industries. Since the material does not harden until it has been heat-treated, the towpregs can be transported and stored for extended periods of time without refrigeration before they are used to form the final product.

The company has developed a range of primary high-performance thermoset epoxy resin matrices for use in the towpregs, with different formulations for different applications. They are used for the manufacture of products in industries such as fire fighting, European Space flight, performance marine (racing yachts), wind turbines and automotive.

For example in the fire fighting industry, towpregs from the company have been used to manufacture composite cylinders for Self Contained Breathing Apparatus, while in the automotive industry there is particular interest in the use of the composites in hydrogen powered vehicles.

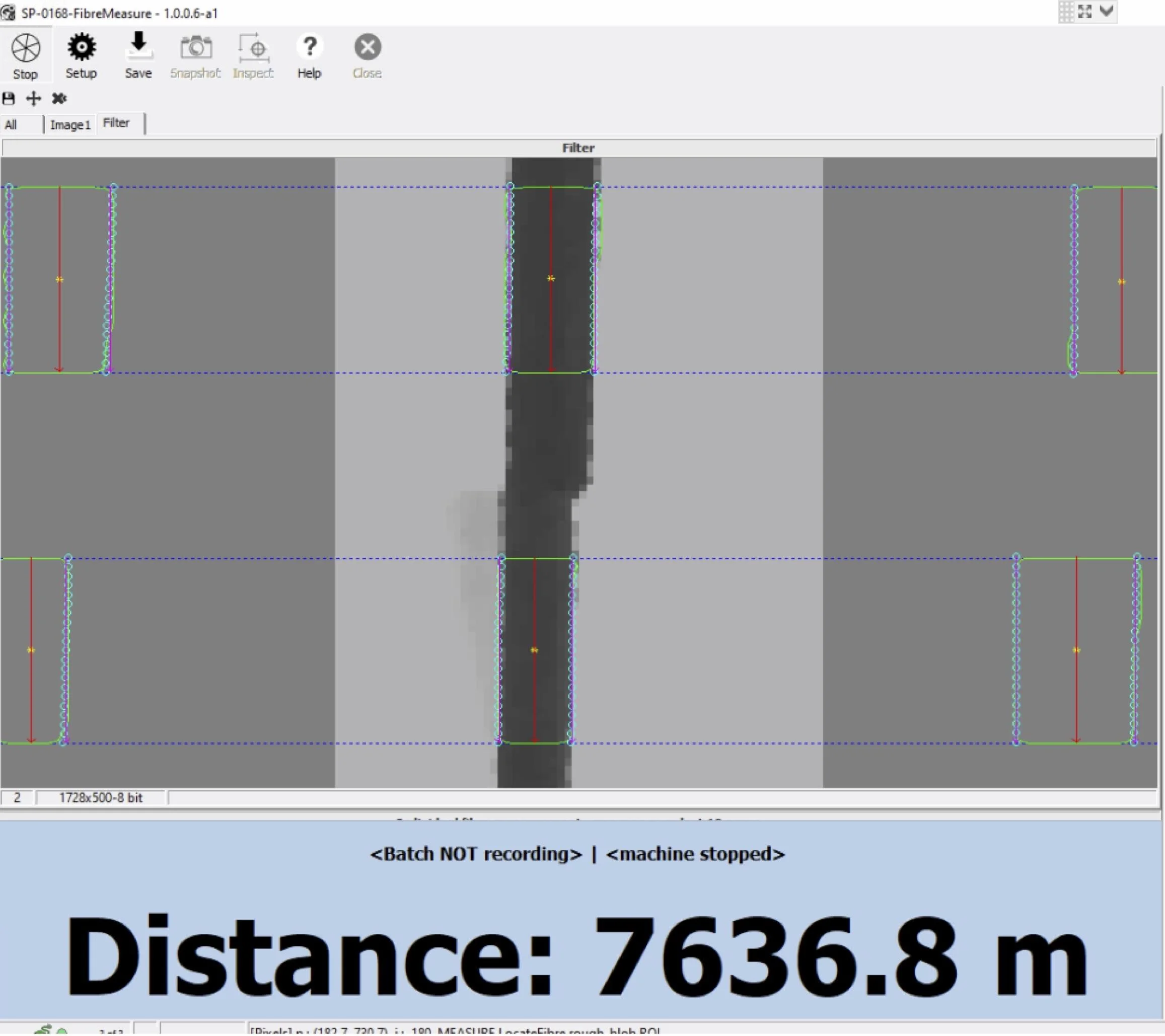

An automated vision system designed by Scorpion Vision provides real-time, high accuracy non-contact measurements of the fibre width from the entire length of the material as it is wound onto the spool.

The system consists of a box containing a high resolution camera to allow measurements to the micron level, if required, LED lighting, strobe controller and an industrial PC. It is controlled via a separate touch screen with a custom designed graphical user interface (GUI). High speed strobe lighting is used to eliminate motion blur and effectively ‘freeze’ the motion of the ribbon for measurement. A signal from an encoder on the spool equipment roller is used to trigger the lighting pulse and the camera exposure.

The encoder signal defines the interval between the image captures, and therefore the distance interval along the ribbon for the measurements. A white background is positioned below the ribbon for carbon fibre measurements and a dark background for glass fibre measurements.

This ensures optimum contrast in the images for edge detection. Several image processing tools within the Scorpion Vision Software are used to condition the image for measurement. The software locates the fibre in the field of view and automatically measures the width and other parameters.

The touch screen displays the current average width as well as the length of fibre processed so far. All results are saved locally in a CSV format and at the end of the run they are wirelessly uploaded to the company’s servers.

GET IN TOUCH

We are always delighted to hear from our customers. If you’d like to ask a question, make an enquiry or request support, please contact us through one of the methods below or by using the enquiry form.

Telephone: +44 (0) 1590 679333

Sales: [email protected]

Technical: [email protected]