Projects 3D Vegetable De-Coring

THE CLIENT:

A large-scale salad processing company that grow and process thousands of lettuce for the wholesale market. Operating both in the UK and the EU and with a rapidly growing team, they play a big part in getting those leafy greens on our plates.

THEIR CHALLENGE:

A huge part of their large-scale processing operation is removing the cores from the lettuce so that the leaves are loose for packing. This was being done manually, meaning they employed large teams of people, often seasonal workers, to de-core the lettuces by hand. This very quickly becomes a labour-intensive and costly process.

Aside from the costs, there were problems with consistency and quality. Naturally, with factors such as seasonal workforces and global pandemics, the employee headcount is prone to fluctuation. Not only that, but the quality of cut and removal varies from worker to worker. An operation that is high in cost but low in consistency and efficiency is less than ideal.

OUR SOLUTION:

We knew we needed to come up with a solution that was fast enough to improve performance and productivity, but accurate enough to reduce waste and ensure a quality of cut that was reliable and consistent.

To tackle this issue, we developed an automated optical de-coring system that removes the core using a robot with a de-coring tool.

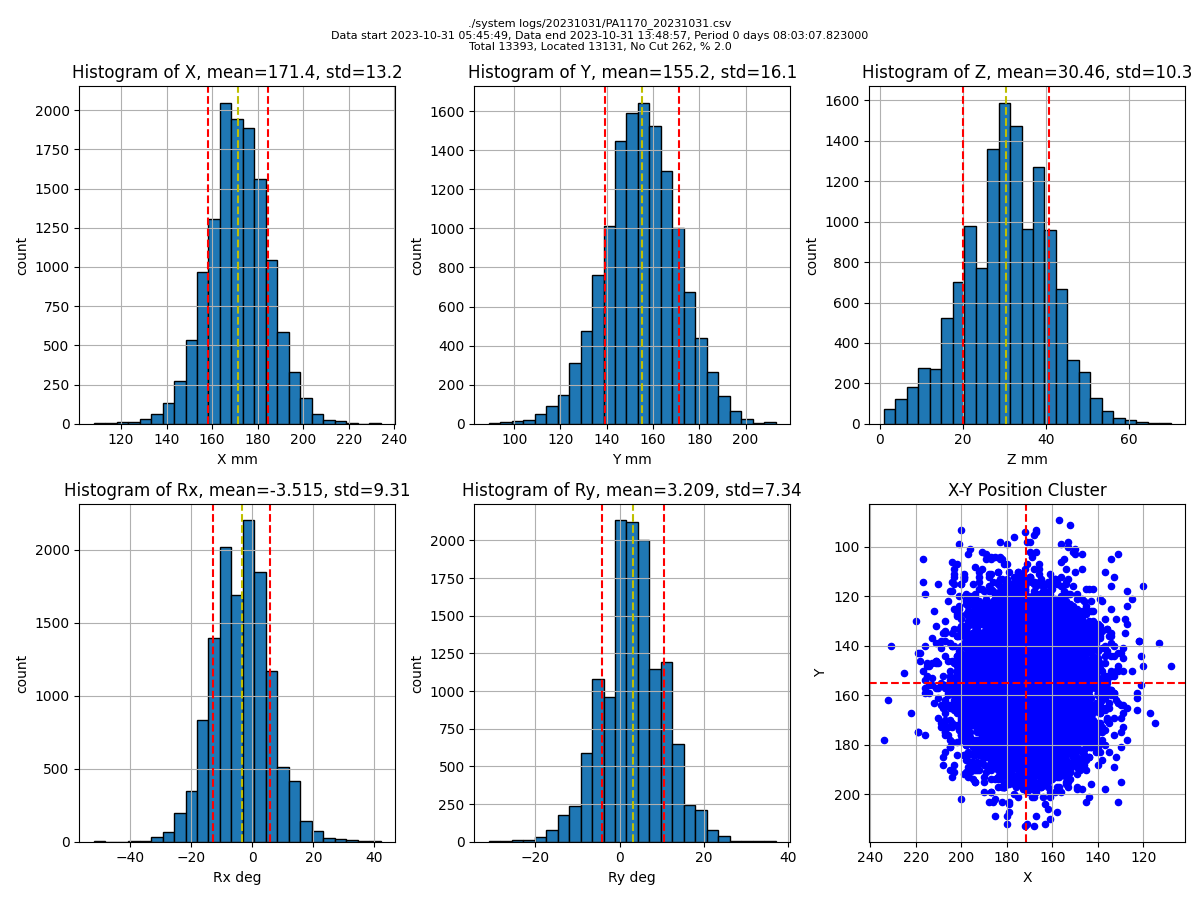

The lettuce are placed into buckets on a conveyor and passed under a Scorpion 3D Stinger camera. The camera analyses the lettuce and calculates at which angle the robot needs to insert the de-coring tool. Watch this video to see it in action.

How does it do that?

Scorpion Vision system uses a combination of 3D vision using stereo cameras and a neural model to identify the stem plate.

This system processes one vegetable per second and, using AI, can handle unlimited variations of products – wonky veg is no match for this robot. Using the 3D system, it calculates the size of the lettuce so that it can send the tool in at the right depth. It estimates the angle of the core, the depth, and the rotation of the lettuce.

Technology used:

- Scorpion 3D Stinger Agritech Camera

- Scorpion Vision 3D+AI Software

- Scorpion Neural PC for Agritech

- Fanuc robot

THE RESULTS:

Our automated optical de-coring system allowed our client to reduce a heavy and unreliable workforce, saving them both time and money that can now be spent elsewhere.

The robot de-cores accurately almost every time, meaning less wastage and more consistency in quality. Our results show the system successfully de-cores 97.5% of the time!

The client now also benefits from increased throughput. One robot can not only achieve the work of 3 people, but it can run for longer, too. So the client can rest assured their produce is being processed efficiently and accurately, spending less money in the process.

__________________________

This solution isn’t exclusive to lettuce, it can be applied to any produce that needs de-coring. It simply needs to be programmed accordingly, and that’s what we’re here for.

Do you have a produce processing operation that could benefit from some optimisation? Reach out to Scorpion Vision to see how we can help.

GET IN TOUCH

We are always delighted to hear from our customers. If you’d like to ask a question, make an enquiry or request support, please contact us through one of the methods below or by using the enquiry form.

Telephone: +44 (0) 1590 679333

Sales: [email protected]

Technical: [email protected]