Founded in 1943 and part of Orkla Foods, Stabburet is a leading Norwegian food producer with ten factories across southern Norway.

It sells well-known brands, such as Grandiosa, Big One, Nugatti, Fun Light, Idun and Chef and these include food products such as frozen pizzas, beverages and confectionery.

Stabburet required an automated quality control system for their pizza production process. The challenge for Stabburet was to inspect 100% of their 7200 pizza dough products per hour, taking measurements of thickness, surface texture, shape and colour. Not an easy-to-solve task, since “living” dough will differ piece by piece compared to classic industrial mass-produced products.

Furthermore, the system had also to cope with different dough sizes and shapes.

The Solution

3D image processing using Scorpion 3D Stinger, a modular and synchronised image processing system (Fig. 1) consisting of a conveyor belt, the image processing hardware and software and an ejection device.

A Scorpion Vision 3D Vision system with a pneumatic ejection device was installed at the first plant. This system uses a gap in the conveyor to record image data from below, as well as from above, so that 100% inspection of the pizza bread can be achieved. The camera below is a linescan device that creates images of the product flow line by line – in the same way that a document scanner works, but in this case, the product is moving over the camera as opposed to the camera moving under the product.

So the initial measurement is from below, inspecting the surface to ensure it is not too dark or too pale.

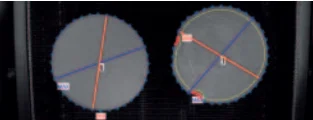

Figure 2 The second step is the surface and thickness inspection using 2D vision to measure diameter, length and width.

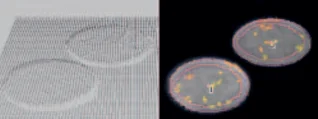

Small and medium deformations as well as edge defects (Fig. 3).

The next step is the surface inspection for dark or pale areas, as previously described for the first inspection of the bottom of the dough (Fig. 4).

The 3D system checks the total thickness, and looks for bubbles, holes and the area-specific thickness for products with different specifications – for example along the edges.

The production lines handle approximately 2500 items per hour. At the end of the line is the ejection device which uses compressed air to force any product that has been failed by the vision system through another gap. For each product to be ejected, a compressed air pattern is generated that measures the profile of the pizza dough so that a good product is not also removed.

The system can run at up to 60 milliseconds and can deal with different dough shapes (round, square and rectangular) with sizes from 100 to 400 mm. For diameter and edge errors, the measuring accuracy is approx. 0.5 mm, and for the thickness, approx. 1 mm. The operator interface consists of a touchscreen at the plant but can also be another location for monitoring.

Text and Images courtesy of Tordivel AS and Polytec GMbH